Do you need speed, cleanliness, precision, or a guarantee that no conductors will be nicked as part of the wire stripping process? Then consider laser stripping from MJM Industries.

Insulating jackets can be removed from wire and cable using many different methods. Before choosing the proper method, you must first define the requirements of your applications. Methods of stripping include abrasion, chemical, mechanical, thermal and laser. While mechanical tends to be the most

popular method, providing speed and accuracy, thermal and laser provide the best opportunity for removing difficult materials while providing no conductor damage. When choosing between the two, one should realize that thermal methods require much more process control and periodic adjustments

in order to retain quality. Thermal processes also often require secondary operations to eliminate rogue strands and ensure quality standards.

For purposes of this discussion, we will spend our time reviewing the pros and cons of laser stripping.

The most essential benefits of laser stripping are the guarantee for no damage to the wire and the

repeatable quality. With laser stripping, there are no limits to as how small a wire gauge can be stripped.

Advantages of laser stripping include the lack of conductor damage, the ability to process almost all insulation types, the ability to hold tight tolerances, the ability to strip a variety of wire forms, and variable strip patterns and the ability to process multiple wires simultaneously.

By using a laser, the insulation will absorb the beam and be vaporized.

The metallic materials of underlying wire conductor will reflect the laser beam, resulting in no damage. An alternative to standard mechanical stripping devices, our laser wire stripper is a computer-controlled machine, much like a CNC router, which uses a laser to burn off the insulation of the wire.

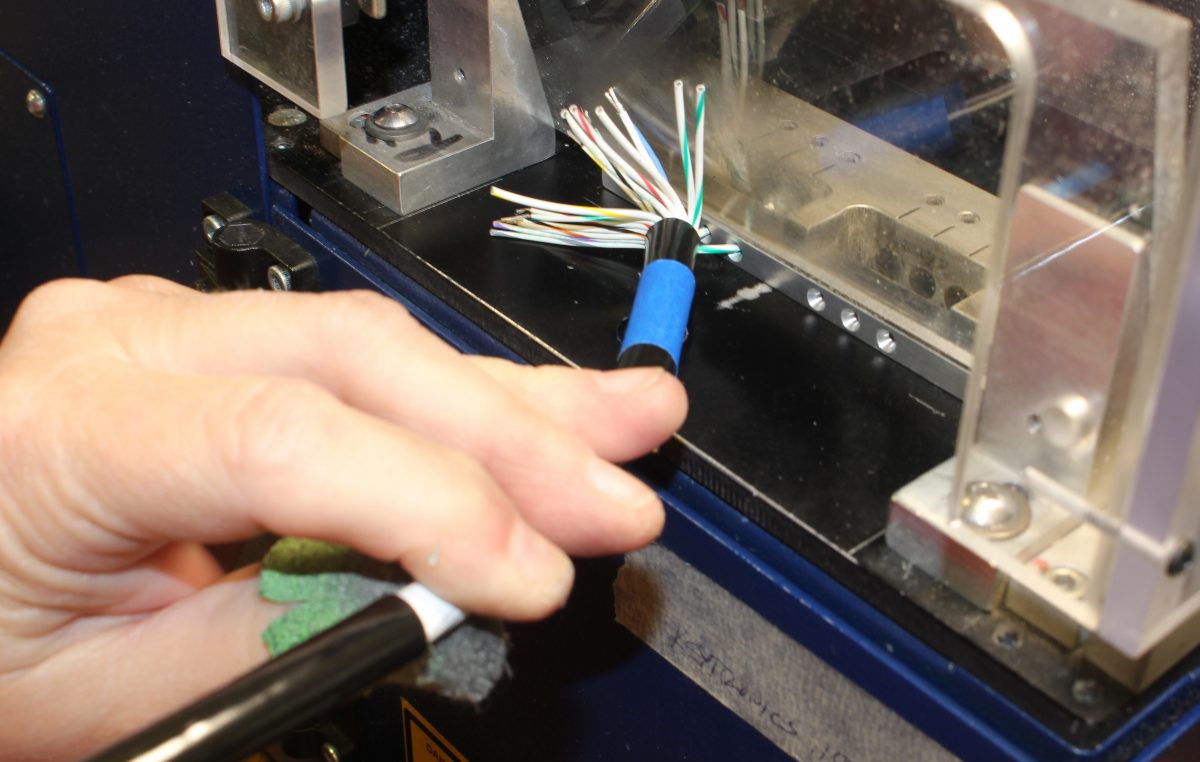

The system consists of a laser, an optical system, controls, application tooling and safety barriers. Laser wire stripping machines are your best choice for very fine gauge wires since they do not damage the conductor. Since laser wire stripping is a non-contact process and the laser beam can be controlled very specifically, it is possible to perform end strip via cross-cut, windows, mini windows, angled cuts and programmable patterns at any point on ribbon or wire cable.

Wire and cable types offered by MJM Industries:

- Single Core

- Twin Leads

- Twisted Pair

- Braided Multi-Conductor Cable

- Tape/Foil Wrapped Cable

- Micro-Coaxial

- Flat Flexible Cables (FFC)

- Ribbon Cable

Applications offered by MJM Industries range from aerospace, aircraft, industrial automation, automotive, military, test and measurement, and medical industries. Some typical devices which could require laser stripping include medical drills, hearing aids, catheters, pacemakers, ultrasound transducers, air bags, small motors and actuators and other related devices requiring Class 3 conductor preparation. Our 25-watt dual axis laser stripper has the speed and power to strip varying material types and dimensions.

Features and Benefits of Laser Stripping:

- Accurate and repeatable stripping of wire and cable – no risk

- Processing of multiple wires and cables simultaneously

- End strips, window strips, longitudinal strips, and other patterns available

- Suited for class 3 applications – required by IPC and WHMA

Insulation Materials:

- PTFE/Teflon

- Tefzel

- PVC

- Polyurethane

- Silicone

- Kapton

- Polyimide

- Polyesterimide

- Polyester

- Fiberglass

- Polyethylene

- Nylon

- Enamel Coated

Dimensional Constraints:

- <6.0MM (.24”) outer diameter

- (4.0”) for Ribbon Cable

- <100mm Bed Size 4.0”x4.0” dimensional constraints

MJM Industries offers a complete laser stripping program to meet all of your challenging wire and cable processing requirements.